How to Write Effective Spec Sheets

Whether designing a new product, developing software, or finalizing the details for a manufacturing process, a specification sheet—or spec sheet—is your blueprint for success. An effective spec sheet communicates dimensions, functionality, compatibility, and expectations clearly and concisely. It’s a critical tool for engineers, designers, clients, and stakeholders to stay aligned during every phase of production.

TLDR (Too Long, Didn’t Read)

Effective spec sheets are essential documents that describe a product or component’s functions, dimensions, and materials. Writing a clear and organized spec sheet ensures better product outcomes and reduces delays or miscommunication. Following best practices, including standard formats, simplified language, and visual elements, helps everyone involved—from developers to vendors—stay on the same page. Add FAQs and maintain a consistent document structure for maximum clarity and usability.

Why Spec Sheets Matter

A spec sheet acts as a bridge between the idea and execution. Without it, team members, suppliers, and clients are forced to make assumptions—a sure-fire recipe for costly errors. Accurate, well-constructed spec sheets help to:

- Ensure consistency between the design phase and final product.

- Guide manufacturers with the right tolerances, materials, and procedures.

- Minimize confusion among team members with standardized information.

- Improve collaboration between different departments like design, engineering, and production.

Essential Elements of a Great Spec Sheet

All effective specification sheets share some key components. Though formatting may vary by industry, a solid spec sheet typically includes:

- Title and Version Number: Include the product name, model number, and version for tracking changes.

- Overview: A brief description of the purpose and key features of the product or part.

- Specifications: List out physical, performance, and technical specs such as dimensions, weight, materials, output power, tolerances, temperature range, etc.

- Compliance and Standards: Note any regulatory standards or certifications (CE, RoHS, ISO, etc.) the product needs to comply with.

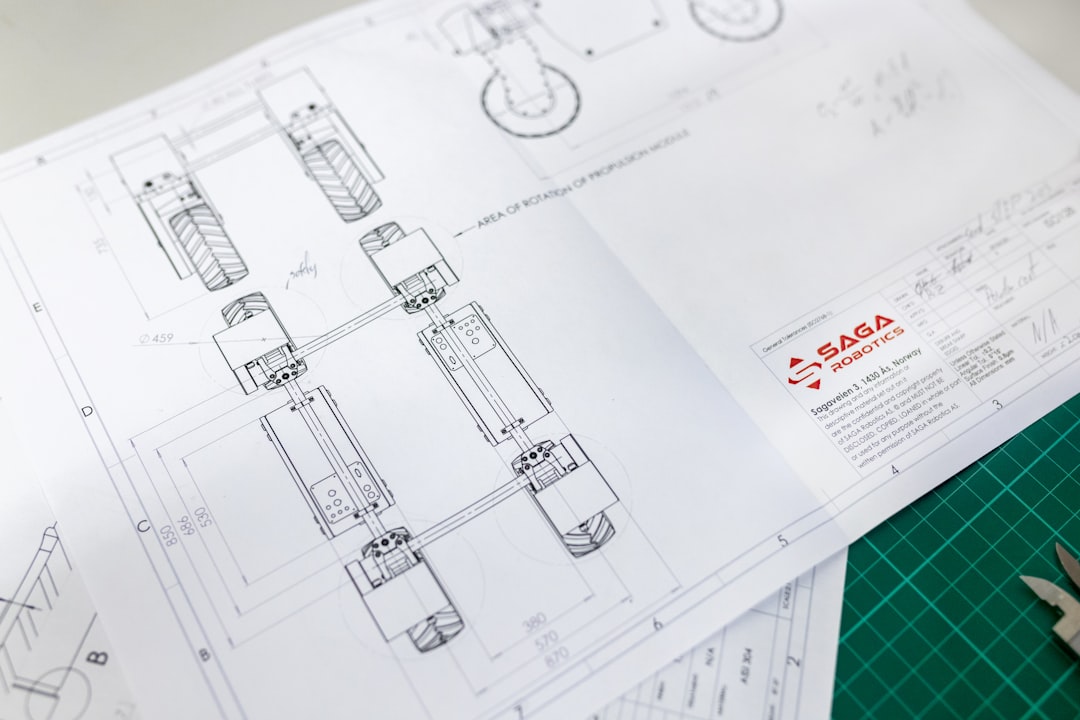

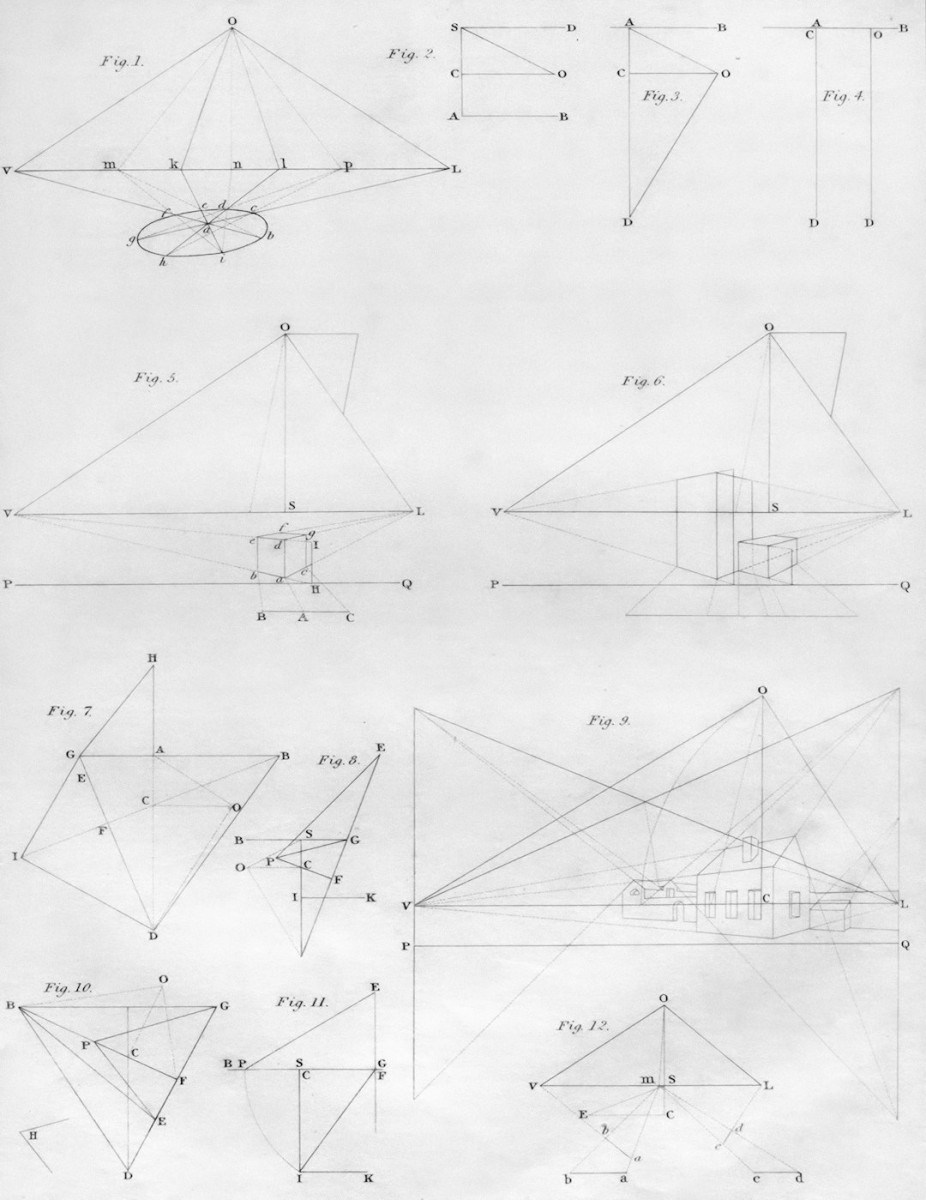

- Visual Aids: Diagrams, technical drawings, or renderings with labeled components or dimensions.

- Notes and Assumptions: Include any assumptions, special instructions, or notes about expected usage.

- Contact Info: Provide relevant contact details for clarification or support.

How to Write an Effective Spec Sheet

1. Know Your Audience

Before diving into technical jargon or laying out measurements, identify who will read your spec sheet. Is it meant for a machine operator, a software developer, or a supplier who speaks a different language? Tailor the language and the level of detail accordingly. For example, internal spec sheets for engineers may assume a base technical knowledge, while vendor-spec documents should be written in simpler, globally understandable terms.

2. Use a Consistent Format

A consistent layout makes your spec sheet easier to scan and quicker to update. Most spec sheets use tables and bullet points for easy access to individual data points. Use standard measurements (metric or imperial, as needed) consistently throughout the document and avoid unnecessary abbreviations unless they are universally recognized.

3. Be Clear and Concise

A good spec sheet doesn’t overload the reader with information. Only include the details necessary for the team member or vendor to carry out their tasks. Clear, action-oriented language helps reduce misinterpretation. Avoid vague terms like “high-quality material” and instead specify “304 stainless steel” or “polycarbonate, impact-resistant”.

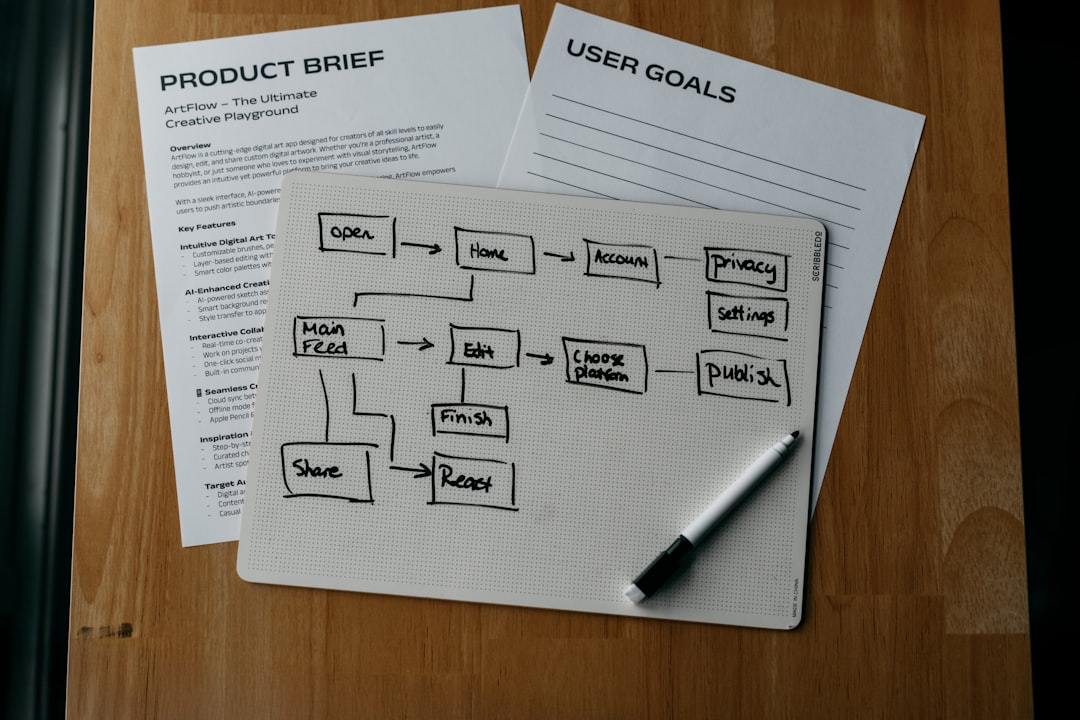

4. Use Visual Elements

When creating spec sheets for physical products, a picture is often worth a thousand words. Include CAD drawings, labeled diagrams, or exploded views if applicable. For software-related spec sheets, UI mockups or flowcharts can provide similar value. Make sure your visuals are high resolution and annotated with clear legends and labels.

5. Include Tolerances and Thresholds

When it comes to measurements or performance metrics, always define tolerances. This tells manufacturers and engineers what level of variation is acceptable. For example, instead of saying a component is “5 cm,” say it’s “5 cm ± 0.1 cm.” This prevents production errors and improves quality control outcomes.

6. Update and Track Versions

Spec sheets evolve over the course of development. Version control prevents outdated specs from accidentally making their way into final designs or production lines. Always include version numbers, dates, and a changelog section. This creates traceability and accountability across teams.

7. Make It Accessible

Distribute your spec sheet in universally accessible formats like PDF. If the spec sheet is stored in a shared environment (like a company intranet or cloud service), maintain edit permissions to control updates. Ideally, centralize your spec sheets in a versioned repository or product data management (PDM) system.

8. Collect Feedback

Before finalizing a specification, circulate it among different departments or external stakeholders who will use the sheet. Ask for feedback on clarity, completeness, and compliance. This peer-review step ensures your spec sheet works as a functional document, not just a piece of documentation.

Tips for Different Industries

Not all spec sheets are created equal. Here are some best practices by industry:

- Manufacturing: Include mechanical tolerances, materials, safety guidelines, and assembly diagrams.

- Software Development: Add API parameters, system requirements, version compatibility, and flowcharts.

- Consumer Electronics: Use detailed port layouts, battery specifications, operating temperature ranges, and certifications.

- Construction: Note building codes, material specifications, wind loads, and fire ratings.

Common Mistakes to Avoid

Even seasoned professionals occasionally make their spec sheets harder to use. Below are a few common traps and how to sidestep them:

- Overuse of Technical Jargon: Don’t assume everyone knows what “HV03 compliant” means. Provide definitions if needed.

- Unclear Numerical Ranges: Always define whether a value is an average, maximum, minimum, or recommended range.

- Missing Units: A number without a unit is meaningless. Always specify cm, kg, GHz, etc.

- No Visual Aids: Leaving out diagrams or renderings can make your spec sheet much harder to interpret.

Conclusion

Spec sheets are a vital component in nearly every field where precision matters. Whether detailing the properties of a smartphone component or establishing the standards for a software module, a good spec sheet balances clarity, brevity, and completeness. When done well, it serves not just as a document, but as a roadmap toward a successful and traceable product lifecycle.

Frequently Asked Questions (FAQ)

- Q: What is a spec sheet?

A: A specification sheet (spec sheet) is a document that outlines the key technical and functional characteristics of a product, material, or component. - Q: Who uses spec sheets?

A: Engineers, designers, product managers, vendors, quality control teams, and clients use spec sheets to understand and align on product requirements. - Q: What’s the difference between a datasheet and a spec sheet?

A: While both documents provide details, a datasheet typically offers performance metrics and operational parameters, while a spec sheet may include more instructions, tolerances, and design criteria. - Q: How often should a spec sheet be updated?

A: Anytime there is a change in the product design, materials, measurements, or regulations affecting the product, the specification sheet should be revised. - Q: Can I use templates for spec sheets?

A: Yes, using templates can ensure consistency and save time, especially when you have to create spec sheets for similar products or systems.